SGRT’s goal is to encourage and build research and study on Glass, Profiles, Façade, and Fenestration and their associated materials and also focus on the quality and performance of materials, their application, and functional aspects in buildings. Building a code of practices for the use of structural glazing in the country through continuous research and interaction with the Bureau of Indian Standards. Sustainable energy performance in facades and systems In India through structural integrity and durability.

Research study on “Structural glass as a building material in Indian high rise buildings”

India has taken the lead role among the developing countries with its economic boom and globalised market trend and this has made the major cities of India to expand exponentially; to minimize the effect of exponential expansion of the cities to the urban commuters and to maximize the utilization of valuable and space and productivity, development of high rise buildings in India had become inevitable.

Globally various materials are used in the construction of high rise buildings for economic reasons which aid in quick construction and gives modern aesthetics to the building. In this modern era, due to the various innovation and invention in processing of annealed/raw glass, has widened the scope of architectural glass usage and choice of selection; according to the requirement and performance. And thus the architectural glass has really taken a wide range of engineering applications, particularly in construction engineering. And due to these advantages, usage of glass and glazing has become one of the integral parts in Indian high rise building for fulfilling the criteria such as.

Ease of construction: Construction of the glass and glazing system to the building is swifter since most of the systems are completed in the factory level, maintaining the quality throughout the process.

A real world building selected for researchReduction of dead weight: Dead load due to the self-weight of the glass and glazing system on the structural members of the high rise building is low.

Serviceability: Due to the glass and glazing system sleekness in the building, lot of valuable floor space is saved for usage.

Day lighting and Thermal comfort: Glass and glazing system allows abundant day lighting to the building there by reducing the need of artificial lighting in the building and ultimately saves the energy requirement of the building.

Therefore a research study carried at SGRT Facility funded by Glazing Society of India (GSI) aims at investigating the usage of architectural glass and glazing material as a building material in the high-rise building along with the commonly used conventional materials to understand the optimum usage of architectural glass with conventional materials; in maximizing the performance and economic feasibility in construction and thee by creating a strong background document for the experts and engineers of Indian construction value chain to analyze and understand architectural glass as a building envelope material with is structural functions and utilities in high-rise building.

The research study would cover the following aspects:

Project Done by: Mr P Midhun Babu, Dual degree, M.Tech in Structural Engineering, 2010 batch.

Guidance by: Dr S Arul Jayachandran, Professor, Structural Engineering, Department of Civil Engineering.

Safety Glass was preferred for most structural members to avoid injury when the member fails. Currently there are no glass design standards available in India which deals with the in-plane behavior of glass panels. For design of facade systems in India, ASTM/Euro codes are normally followed as Indian codes don’t address such information this necessitates study on the structural performance of glass panels for Indian conditions.

There are two types of loading that come on a glass structure. They are in-plane loading and out of plane loading. A pane of glass is usually designed to carry out only out of plane loads and the only in-plane load for which it is designed is its self-weight. But structural glass is subjected to numerous loads like wind, snow, thermal stresses, earthquake loads, live loads and impact load. For glass to be used as a structural member, it should be designed to resist in-plane loads. When glass is used as a load bearing wall or column it should resist in plane compressive loads. But earthquake induces both in-plane and out of plane load to a glass façade system. Out of plane loading causes bending of the panel member and is mainly governed by wind load design. In plane loading causes shear in the panel and connection which is governed by seismic design.

The study is limited to only in-plane behavior of the glass façade system under loading. Effects associated with the out of plane behavior like buckling and vibration are neglected in the study. Only laminated glass panel is covered under this project which is commonly used as the infill material in façade system due to its post breakage behavior Long term loading and temperature effects are neglected in the study. The study also attempts to suggest improvements in the analysis and design, connecting systems, supporting structure, glass panel, sealants and adhesives to enhance seismic performance.

Project Done by: Mr Kowshik Chilamkurthy and MrSai Praneeth Devunuri, B Tech Civil Engineering, IIT Madras.

Guidance by : Dr S Arul Jayachandran, Associate Professor, Structural Engineering, Department of Civil Engineering.

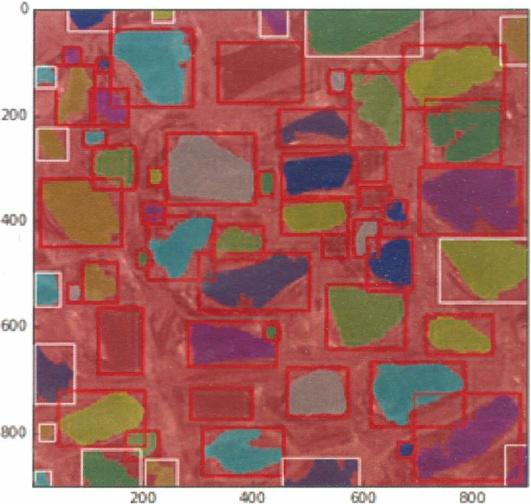

Fragmentation test is the universal testing method and integral regulation addressing quality control to assess the safety breakage pattern of the toughened glass. In most of the centres around the world it is performed manually by breaking the toughened glass and counting the number of fragments inside a 5 cm square drawn on the broken glass. Therefore we took the scenario and created an algorithm to detect the fragments inside the 5 cm square on the broken toughened glass. This model would enable more reliable and accurate interpretation of the test. The coding for the model is written in python language using skimage which is very well known library for computer vision. This process takes advantage of mathematical morphology algorithms, filter algorithms, pre-processing algorithms to perform robust pre-processing and segmentation. The model would auto recognize the fragments which are on the border lines of the square and count it as half particle and the fragments inside the square as full particle as per the Indian and International standard norms.

Project Done by: Mr Omkar Sukumar Powar, Research Scholar.

Guidance by : Dr S Arul Jayachandran, Associate Professor, Structural Engineering, Department of Civil Engineering.

Research objectives:

The main aim of this work is to understand the response behavior of Façade system subjected to Wind loading. In order to achieve this goal following specific objectives had to be attained;

Numerical Study on Facade Panel Designing:

Numerical study was performed on load resistance aspect of designing architectural glass in consideration with commonly used design standards in India, namely, AS 1288 - (2006), Draft prEN13474-2 (2000) and Draft NBC of India Part 6: Section 8-Glass and Glazing (2015). Paper titled "Issues in probability based design of architectural glass in buildings" was published in the International Conference on Advances in Glass Sciences and Technology. Summary and selected results of the work are presented below.

This paper is categorized into two parts, where the first part provides an overview of the design procedures and discuss the limitations of the commonly used design standards in India, namely, AS 1288- (2006), Draft prEN13474-2 (2000) and Draft NBC of India Part 6: Section 8 -Glass and Glazing (2015). Structural design of glass panel basically involves arriving at the minimum thickness of glass required to span over the considered dimensions, depending upon the load resistance of the specific type of glass. The basis for calculation of load resistance is different in all the design standards. The per EN 13474-2 is derived from Design Equivalent Load resistance (DELR) method and also has influence of Shen and Siebert models, AS 1288 is based on tensile stress developed on the glass surface where as the NBC is based on empirical formulations.

Second part of the paper discusses the studies made by authors regarding the issues of design of architectural glass. The study encompasses all type of single glass systems such as Annealed, Heat Strengthened and Toughened glass products. Study is performed with help of specially developed computational aid which is capable to isolate one particular factor and freeze all other factors, to capture the effect of that considered factor on the thickness of glass. The major design issue is the ability of the architectural glass to withstand the primary load - the wind load. A few typical results of the study are briefly enumerated below.

Aftermath of Cyclone VARDAH - (Reconnaissance Survey)

Cyclone Vardah had its landfall on the eastern cost of India on 12th December 2016. -The extreme wind evens lie Cyclone Vardah, though very unfortunate, provide the opportunity to study the possible failure patterns and come up with the corrective measures so that we can face the challenges posed by nature in a better way. This work is one such effort to elevate the performance standards of the Façade system in urban area when subjected to the extreme wind events.

With this objective, three days long, intense post-disaster field investigation was conducted. Around 210 km of road length, which encompasses the most affected urban areas in and around the Chennai city were examined. Process involved collection of the façade failure data in photographic and interview format, and then performing a detailed relative damage potential analysis of all the failures observed. After post-processing, the acquired façade failure data and details of the analysis carried out were compiled and systematically documented in form of the report named as "Façade Failures over Urban Landscape: Aftermath of Cyclone VARDAH'. Glimpse of façade failures observed and some key points are presented below.

Project Done by: Ms Kaviya Piriyah, B- Tech, Civil Engineering.

Guidance by: Dr S Arul Jayachandran, Associate Professor, Structural Engineering, Department of Civil Engineering.

Front facade of the Vizag airport was damaged during the Hudhud cyclone attack and rehabilitation on the building was made at full swing, starting with the design evaluation of facade members including aluminium mullions and transoms of the front facade along with its MS supporting structures.

Stress and deflection values extracted through STAAD pro model were then compared with the allowable limits from Indian code 15-7885 for the design compliance. The architectural glass selected for rehabilitation work were then tested for its characteristic, safety and structural performance at Structural Glass Research and Testing (SGRT) Facility, IIT M.

The stress and deflection of the architectural Double Glazed Unit (DGU) with the laminated pane fixed in the airport façade were analyzed with design software and the laminated panels were analyzed using the Anna University's mineral engineering laboratory facility for high pressure loads to understand ultimate design strength.